The fashion commerce is inside the midst of a profound transformation. Technological enhancements are reshaping either side of our enterprise, from manufacturing and supply chains to purchaser engagement and retail experiences. As we stand at this intersection of customized and know-how, it’s important to know how these developments can help us scale profitability and streamline processes with out dropping the artistry and craftsmanship that define our producers.

At Sartoria Vienna and the shirt dandy, premium menswear producers specialising in made-to-measure tailoring, we’re embracing the alternate options know-how affords whereas staying true to the values of top of the range and personalisation. On this text, I’ll uncover how three key utilized sciences – 3D configurators, cell physique scanning and pattern automation – are revolutionising not solely our enterprise however moreover the fashion commerce at huge.

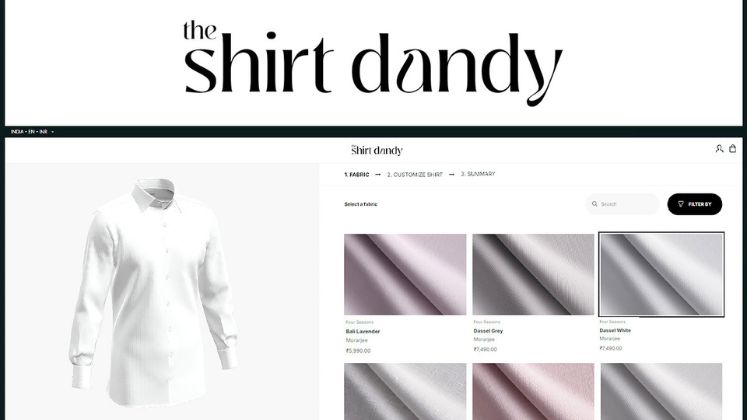

3D configurators: Enhancing purchaser engagement and personalisation

Customisation has on a regular basis been the hallmark of high-end vogue, significantly inside the bespoke garments market. Traditionally, this course of required time-consuming consultations and repeated fittings to ensure the correct garment. However, 3D configurators are transforming the customisation experience.

We utilise a classy 3D configurator that allows purchasers to design their garments on-line in real-time. Shoppers can select supplies, choose specific cuts and visualise their remaining product sooner than a single sew is made. This know-how enhances purchaser engagement, letting them co-create their garments with ease, all from the comfort of their homes.

The revenue for us as a enterprise is twofold: we are going to seize the patron’s imaginative and prescient with fewer touchpoints, reducing the potential of miscommunication and concurrently streamline our ordering course of, as a result of the patron’s preferences are instantly built-in into our manufacturing system. This not solely shortens the product sales cycle however moreover leads to elevated purchaser satisfaction, driving repeat enterprise and referrals.

Mobile 3D physique scanning: Precision match wherever

One in every of many greatest challenges in custom-made tailoring has on a regular basis been to achieve the correct match. Traditionally, this involved detailed hand measurements and numerous in-person fittings. However, the occasion of cell 3D physique scanning know-how has been a recreation changer, considerably in tailoring.

Mobile 3D physique scanning permits prospects to utilize their smartphones to grab precise physique measurements in minutes. We’ll implement this know-how shortly to permit distant fittings, allowing purchasers from all through the globe to experience the correct match with out even moving into our retailers.

This know-how has the potential to develop our purchaser base, breaking down geographical limitations and making a seamless, tech-driven purchaser experience. Moreover, the precision of these scans reduces the margin of error, resulting in fewer adjustments and sooner provide cases, which boosts normal profitability by slicing costs associated to alterations and remakes.

Pattern automation: Accelerating manufacturing whereas sustaining prime quality

Whereas customisation has on a regular basis been on the core of bespoke vogue, it historically required a labour-intensive, time-consuming course of for pattern creation. Each new garment involved hours of handbook work to create the correct match for a client. With the arrival of pattern automation know-how, nonetheless, we’re ready to streamline this course of significantly.

Ultimately, pattern automation software program program could be utilized to translate a purchaser’s distinctive measurements from 3D physique scans instantly proper right into a digital pattern, which can be then optimised for manufacturing. This not solely saves time nevertheless ensures that every pattern is strictly aligned with the consumer’s dimensions, leading to a relentless and proper match every time.

Previous this, pattern automation reduces supplies waste by optimising materials utilization. In an commerce the place sustainability is increasingly mandatory, this effectivity in manufacturing contributes to reducing our environmental affect, whereas moreover decreasing costs.

Case study: Integration of tech-driven choices on the shirt dandy

Let me illustrate the affect of these utilized sciences by means of a smart occasion in India with a client who’s unable to go to our retailer or meet our travelling tailor on account of journey restrictions. Using cell 3D physique scanning know-how, we would seize his measurements remotely, and through the 3D configurator, he is able to design his custom-made swimsuit with our employees nearly.

As quickly as his measurements are processed, pattern automation software program program generates a digital pattern in a matter of minutes and the swimsuit is achieved inside 7-14 days. The precision of the 3D scanning ensures a near-perfect match on the first try, requiring minimal adjustments.

Your full course of, from design to produce, takes merely two weeks, compared with the traditional 4 to six weeks required for a custom-made swimsuit. By streamlining this course of with know-how, we not solely enhance purchaser satisfaction however moreover optimise our sources and labour, enhancing profitability and reducing lead cases.

The best way ahead for vogue: Embracing know-how for sustainable progress

Because the fashion commerce continues to evolve, embracing know-how is just not an chance nevertheless a necessity. The mix of 3D configurators, cell physique scanning and pattern automation is simply the beginning of a broader shift in the direction of digitisation and effectivity in luxurious vogue.

For producers like Sartoria Vienna and the shirt dandy, these developments will allow us to scale our operations with out compromising on prime quality or craftsmanship. By adopting tech-driven choices, we’re not solely enhancing profitability however moreover providing a superior purchaser experience, the entire whereas reducing our environmental footprint.

The best way ahead for vogue lies on this seamless mixture of customized and innovation, the place the artistry of bespoke tailoring meets the effectivity of current know-how. For these ready to embrace this transformation, the rewards – every for corporations and prospects – are big.

| Thomas Hebenstreit (30), an Austrian finance expert, is the Founder and CEO of two revolutionary vogue producers. He launched the shirt dandy, introducing India’s first AI-powered 3D configurator for custom-made menswear and simply recently based mostly Sartoria Vienna, an expensive bespoke menswear mannequin that features premium Italian supplies, with garments made inside the EU. Thomas has lived, labored and studied in Austria, Germany, Luxembourg, France and India and objectives to redefine how males experience vogue. |