Inside the wake of the current circumstances, awakening of the type commerce has launched up a consciousness about ill-effects introduced on by emissions inside the ambiance. From the changes in product sourcing insurance coverage insurance policies by luxurious producers, to adoption of sustainable fashions by fast type producers, the extent of urgency could also be estimated.

To cater to the elevated demand for sustainable fibre choices, pineapple fibre is providing increased choices to leather-based and accent producers. As a part of eighth model of the Acutely conscious Distinctive advertising marketing campaign, H&M inaugurated its latest assortment made out of sustainable provides. For the first time, a jacket composed of Piñatex, pineapple leather-based, with citrus fruit residues and nettle plant extracts was launched by H&M. “Piñatex could substitute half of the worldwide leather-based market,” talked about President of ‘Ananas Anam’ ( the distributer of Piñatex), Mélanie Broyé-Engelkes.

Being a plant-derived fibre, pineapple fibre is after all obtained making its present a gentle and biodegradable chance for quite a few technical makes use of. Development of know-how inside the type commerce performs an very important operate in driving the change in course of sustainability.

FashionUnited is ready to go for a better varied to leather-based, that is pineapple leather-based, examined and developed inside the new assortment. On the company’s pledge to go vegan, the collections moreover showcased supplies derived from espresso and lotus fibres. Now, the principle focus is on leather-based gadgets to get changed by pineapple leather-based designs.

For such sustainable ambitions, Ananas Aman is rising non-woven, naturally-extracted textile out of pineapple leaves with a texture, coloration and actually really feel similar to that of leather-based. The fabric was a outcomes of the efforts by Dr. Carmen Hijosa, who was impressed by the environmental impression and ethical choices that could be solved using plant-based fibres. “The inspiration to utilize the fibres current in pineapple leaves received right here partially from the utilization of this raw supplies in typical delicate supplies,” talked about Hijosa.

Basically probably the most appreciated half about pineapple fibre manufacturing is that it does not embody use of any heavy metallic oxides and totally different hazardous chemical compounds which can be harmful to manufacturing, people and likewise to the setting. Furthermore, no by-products used are animal derivatives, and are a technique of waste utilisation, together with on to the sustainability energy of pineapple fibre manufacturing. The fabric thus obtained is strong, moisture retaining, breathable, versatile, versatile and displays a lot much less resistance to dyeing and printing.

Due to these properties and wonderful effectivity, pineapple fibre has obtained many awards similar to the Best Innovation Award in 2015, The Grand Designs Hero inside the 12 months 2016, and licensed cruelty-free label by PETA in 2015. Ranging from garments, interiors, to footwear and gear, many producers and celebrities have now built-in pineapple fibre as a various of leather-based in new collections. For instance, these days Livia Firth, an Eco-activist and Film Producer, styled a silver gown designed by Italian designer Laura Strambi for the Met Gala, fabricated from Pineapple fabric ‘PiñatexORO’. Totally different producers like TimeIVChange, Bourgeois and Alexandra Okay. have already started launching collections using pineapple fibres.

Pineapple fibre is an progressive naturally-derived new sort of tissue which is made out of pineapple leaves, a waste generated from pineapple fruit harvest. It was solely after a few years of research, and efforts by Dr. Hijosa, that its potential is seen to the world. “The subsequential step to point out this innovation proper right into a additional robust textile which was moreover commercially viable was the outcomes of some years of research and enchancment,” Hijosa added. Usually, fibres are extracted from the inner flesh of pineapple peels and leaves. The leaves which could elsewise be despatched for compost, are being utilised to extract fibres by a decorticator machine. The manufacturing of fibres is accomplished by the subsequent steps:

- Slicing and Peeling: The pineapple plant is pulled off from beneath the underside; the leaves and peels are parted into bundles vertically sooner than it is manually separated to extract the residual half after fruit harvest.

- Fibre Extraction: The peels and thicker leaves are peeled and picked up manually. The extracted parts are handed by stress rollers in a machine to get the fibres separated successfully. Sooner than extra processing, the excess of moisture and water is eradicated as a result of the leaves transfer by rollers as in a sugarcane juicer.

- Fibre Separation: The peeler and pressed leaves are pulled off the rollers by the operator, robotically separating the fibres, and the pulp will get collected on the bottom.

- Washing and Drying: Extracted fibres are washed rigorously in a tank, squeezed, held on railing and left to sundry. As quickly as dried appropriately, fibres are despatched to spinning centres and the yarn is prepared.

Technical functions of pineapple fibre embody wedding ceremony ceremony and social gathering outfits, casual placed on and formalwear. With the lustrous silky texture, pineapple fibre is getting used as an alternative choice to traditionally used pricey cotton in utility placed on. PALF (Pineapple Leaf Fibre) is utilized in aggrotech, hometech and clothtech textiles. From ropes, to baggage, mats, linens and leather-based seatings, PALF will be utilized alone or in blended sort with totally different fibres to modify additional water consuming fibres. They’re positioned among the many many best progressive entrants inside the paper manufacturing, and composite manufacturing commerce. With its multifarious dietary nutritional vitamins, minerals and compounds, PALF finds functions inside the therapeutic, magnificence and pharmaceutical industries as successfully.

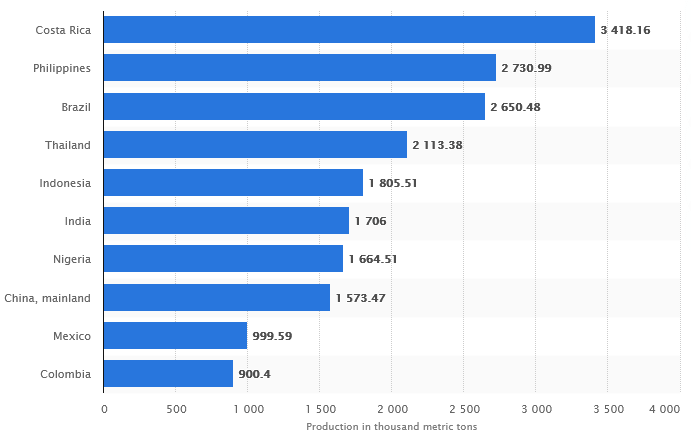

Although, there are an entire lot of potential benefits of using pineapple leaf fibre, there are some pitfalls that may not be neglected. Inside the space of Costa Rica, circumstances have been witnessed the place pesticides’ dealt with pineapple leaves have been utilized in making PALF, which was not as biodegradable as a result of the untreated leaves. Troublesome the scope of pineapple fibre derivatives inside the current state of affairs, critics raised the aim of ‘how ecological is the pineapple fibre really?’ which is however to be answered. However, processing of fibres to create desired output usually forces the fibre to endure chemical therapies. Presently, it is acknowledged by experiments that 16 pineapples (roughly 480 leaves) are required to manufacture a bit better than 10 sq. ft. of fibre, which is 20 per cent cheap than leather-based. Thus, pineapple fibre is definitely a comparatively sustainable and ecological varied to leather-based and synthetic fibres.